The history of grain grinding is a history of innovation and progress; at the heart of this progress lies the grain separator. This extraordinary machine plays a key role in the grain cleaning phase, guaranteeing the quality and purity of the flour. It is, in fact, one of the first machines to be found in the first cleaning section, as a sifting machine that separates the various parts by exploiting their different sizes. Its function is to remove impurities smaller and larger than the grain. Normally, the separator is followed by an aspirator, which sucks in light impurities with a flow of air.

Through the years, we have witnessed the evolution of different models of grain separators, each with its own distinctive characteristics and contributions to the grain processing industry. Let’s take a closer look at some of the most iconic models in OCRIM’s history.

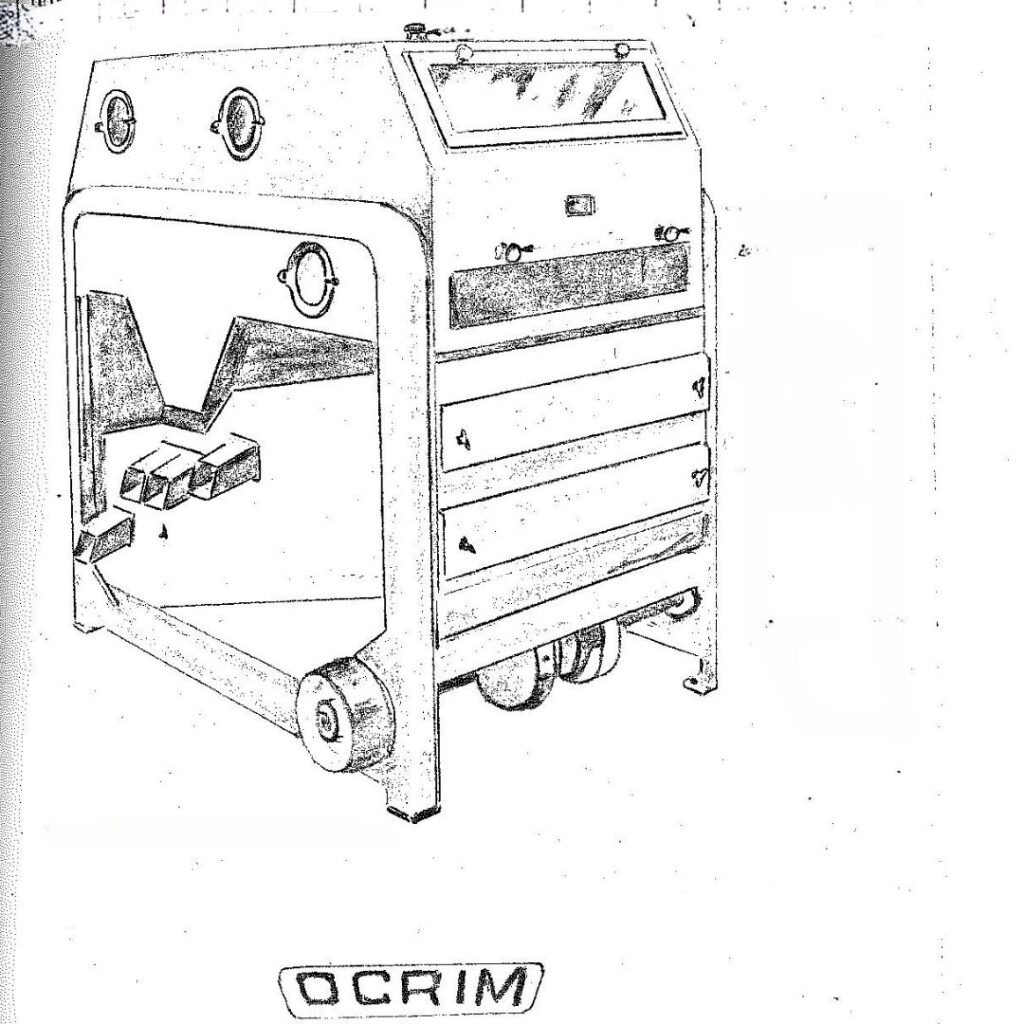

The 1950s

Among the first models, the SEM, SF and SFV stand out, representing a milestone in the evolution of the grain separator. A metal frame, a perfectly airtight sheet metal expansion chamber and an oscillating body with three stacked sieves are their essential parts. More advanced models envisaged the incorporation of a magnetic instrument in the product outlet area to retain ferrous bodies, ensuring even more thorough cleaning. The drive was a perfectly balanced eccentric shaft mounted on ball bearings, thus ensuring constant oscillation resulting in the smooth operation and stability of the machine. Each separator was equipped with a central or independent suction chamber with a fan built into the separator (Mod. SFV). Double separators consisting of two simple couplings were of normal construction, and on request, both these and those could be supplied in wood (Mod. SEM and SEMD).

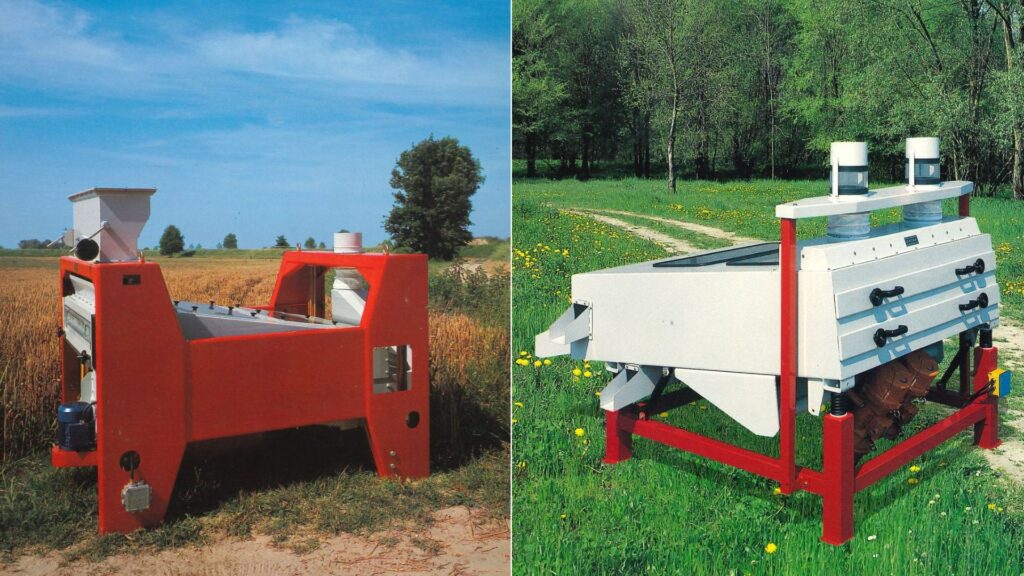

The 1970s

With the introduction of the SCK/S – SCK/D model, the industry has seen a further evolution in grain separator design and performance. These separators, equipped with a vibrating body made of electro-welded sheet metal with two stacked sieves, offer excellent grain cleaning, guaranteeing optimal yield in cleaning operations. The use of hardwood sieves, suspended by elastic elements, ensures effective cleaning and easy replacement of gaskets.

The 1990s -2000s

The SPV model, still characterized by a vibrating body in electro-welded sheet metal with stacked sieves, presented some innovations compared to the previous model, such as, for example, the upper part of the sieving body made up of large transparent doors for direct inspection of the process. The latest model, named SPR, introduced in the 2000s and currently available on the market, has brought grain separator innovation to new heights. It is always characterized by a sifting body in electro-welded sheet steel, consisting in two sieve decks arranged with two different and opposite inclinations; it has a rotary motion. This type of motion, combined with the fact that the product runs over the entire upper sieve and then along the entire lower sieve, guarantees a high classification degree. It is important to underline that in this type of separator, both for the first classification and for the second, the product has the entire surface of the sieve available. Furthermore, the machine is always supported by flexible joints on a sturdy base frame like the previous model, but in this latest version, they can be placed either on the floor or suspended (in this case the structure is supported by fiberglass reeds).

The history of our grain separator is, therefore, a testimony to the incessant pursuit of excellence in the cereal processing industry. Through continuous innovation and commitment to quality, we continue to lead the industry towards new frontiers, ensuring excellent products for our customers.